Are Plastic Pallets Really Expensive?

Guest blog by Amanda Nichols from MHI Member Company Georg Utz, Inc.

Is a wooden pallet really less expensive to use than plastic pallets? What are the advantages of plastic pallets? Is the life span of the pallet proportional to its price? Many managers of companies that use pallets on a daily basis probably ask these questions. At first, the purchase of plastic products is stereotypically associated with a higher price and thus a more expensive investment. However, is this really the case in the long run? It is worth considering a few arguments, often overlooked during the cost analysis.

Repairs and Utilization

Anyone who uses wooden pallets in a warehouse or production facility knows that, just like any other product, they have some things that could be considered difficult. Falling splinters, nails or even larger pieces of pallets force continuous cleaning and countless repairs. On the other hand, for products that can no longer be repaired, space for storage or disposal must be obtained. All these additional activities related to maintaining the quality of the wooden pallet should be taken into account.

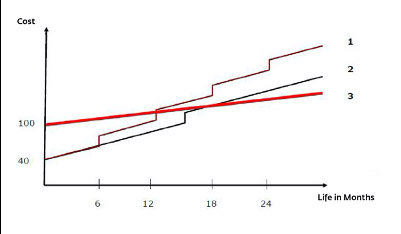

The chart below illustrates the comparison of costs for using 3 pallets:

- Wooden, dried pallet operated in humid conditions, outdoors

- Wooden, dried pallet operated in dry conditions

- Plastic pallet

The test showed that pallet No. 1 required the first repairs after six months of use, especially during periods of large temperature changes during the day (moisture and frost weaken the pallet). The increase in the operating costs of the plastic pallet (No. 3) over time is only due to the assumption that the pallet will be washed after a certain number of cycles. After the first year, the cost of using a wooden pallet was equal to the purchase prices of a plastic pallet.

Hygiene and Cleaning

Plastic pallets are much easier to clean and eliminate micro-organisms and bacteria. They can be washed and disinfected without any obstacles, and thus effectively eliminate the risk of mold. This is of great importance especially in the food industry, which imposes very strict requirements in this respect. Hygienic pallets with a completely closed surface, without external ribbing in direct contact with food, are particularly useful in this industry. Simply wash them to meet specific requirements. Wooden pallets, however, must be subjected to additional thermal or chemical treatments, increasing their operating costs. The use of contaminated pallets results in very costly epidemiological consequences.

Use in automatic warehouses

The use of wooden pallets in the increasingly popular automatic warehouses and distribution centers can disrupt the operation of the conveyor (or other devices), if a piece of wooden pallet comes free. Any downtime of transport lines or equipment is a consequence of significant costs and extension of the order processing time.

Length of Life

Plastic pallets are made of high quality plastic, which makes them resistant to abrasion and ensures a long service life. The durability of a wooden pallet is sometimes artificially extended. Plastic pallets are typically considered in good use for at least 10 years whereas wooden pallets rarely reach one year without repairs.

Utilization and Ecology

It is especially important to think about what happens to the pallet when it is no longer suitable for further use. The plastic pallet can be 100% processed and used for the production of new pallets or other plastic products, thus reducing overall CO2 emissions.

The use of plastic pallets is very often a change in habits and standards in logistics. However, it is worth taking a closer look at operating costs today, because in the long run the ROI of plastic pallets is often worth the investment. By using plastic pallets, you gain a product with a permanent tare, which will serve for many years, can be more hygienic to use, and can cause less problems in everyday use.