Companies’ IT Spend Focus Not Aligned With Supply Chain Visibility Goals

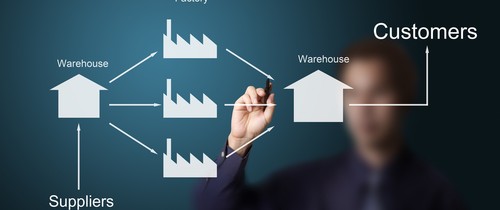

Companies continue to focus their information-technology spending on automation within their own businesses rather than their extended supply networks, a misalignment between IT and business leaders that runs counter to industry goals of advancing supply chain visibility and agility, a new study from Supply Chain Insights LLC suggests.

Visibility in the extended supply chain is in its infancy as most companies remain focused on enterprise automation, even as many outsource manufacturing and logistics, the study finds. While companies value supply chain network visibility, actual performance falls significantly short, especially with regard to order coordination, first-tier suppliers, and transportation and logistics, it says.

“The implementation of supply chain visibility grows more important with outsourcing and the building of supply chain relationships in the extended network. IT programs are not aligned to close the gap. Making this happen quickly is essential for business continuity, corporate social responsibility, and the prevention of major supply chain outages,” the report by Supply Chain Insights founder and CEO Lora Cecere says.

“The extended supply chain is too important to be connected primarily with spreadsheets, faxes and phone calls.”

Supply Chain Insights conducted an online survey of 78 supply chain, IT and cross-functional business leaders at manufacturers, retailers, distributors and third party logistics providers. Fifty-nine percent of respondents head supply chain operations for global manufacturers.

“Companies want to build end-to-end value networks. The supply chain processes are more dependent on trading partners and interactions of the extended supply chain; but the IT capabilities are largely based on electronic data interchange (EDI) and spreadsheets. It is inadequate. IT spending is focused on enterprise resource planning (ERP) which automates the enterprise, not the network. This is a conundrum for the supply chain leader,” the study says.

“Companies are seeking new and deeper forms of supply chain visibility through business networks. It takes many forms. It is foundational to deliver on the promise of agility. They want to be more agile and the current IT architectures are not meeting this need,” the report says.

Nearly half of respondents report that ERP was a major focus in last year’s IT budgets, according to the study. “The spending is so substantial that line-of-business leaders are struggling to find funds for non-ERP supply chain visibility initiatives; and in general, the IT team is not in general agreement that the visibility gap cannot be closed through ERP,” the report says.

Supply chain leaders, in contrast, aren’t confident that ERP can close most visibility gaps in the extended network, according to the study.

Ninety percent of survey respondents reported some level of outsourcing, with nearly a third outsourcing at least 40 percent of their manufacturing, research firm Supply Chain Insights says. Fifty-five percent outsource at least 40 percent of their logistics by volume, the study says.

Among recommendations, the firm says business leaders need to work with IT to align IT spending and plans for supply chain visibility. Companies should rationalize ERP spending, maximize private networks and qualify new forms of public supply chain visibility solutions, the report says. Supply Chain Insights cited work being done by Elemica for process industries, Exostar for aerospace and defense, E2open for high tech and electronics, GXS for healthcare, and GT Nexus for transportation and logistics.

“Companies claim to be building end-to-end supply chain visibility systems, but as this study indicates, these claims are not accurate,” Greg Johnsen, founder and chief marketing officer of supply-chain-management platform operator GT Nexus said in a press release.

“Business leaders recognize the value of supply chain visibility but the approach being deployed on the IT side is proving to be outdated. The gaps in current supply chain capabilities are large. ERP is effective within the four walls of the business and EDI is effective in moving transactional data. But business networks require new solutions for supply chain visibility and agility. Current IT architectures are not meeting this need,” Johnsen said.

Click here to view the complete report.