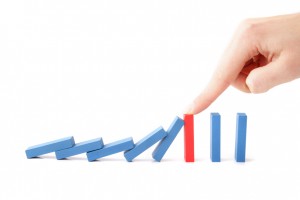

Managing Risk

From MHI Solutions

Weather events around the world disrupts production of a key component. A port strike delays imports. An equipment breakdown strands a shipment. These require action in the moment. But anticipating these events before they happen can make the difference between surviving and succeeding.

“You have to have increased sensitivity in your company to the severe impacts that supply chain disruptions can have on your business and your value,” said Gene Tyndall, executive vice president of logistics consultant, Tompkins International.

The stakes are high: a Georgia Tech study showed that companies can lose as much as 9 percent of their value with a major supply chain disruption; another study by the same university calculated that it can take two years to fully recover.

It’s no wonder that supply chain risk management has become a hot topic. Steve Banker, service director, supply chain management for ARC Advisory Group, the technology research and advisory firm, states, “There are some types of supply chain risk that you can’t totally avoid; you don’t know that there’s going to be a hurricane entering New York City. But you can plan ahead and think about how you’re going to respond. If you can’t totally control it, you can mitigate it.”

But how?

Click here to read the full article.