Why Low Rack Column Guards Matter in Warehouse Safety

Guest blog by MHI Member Damotech

In a busy warehouse, accidents can happen fast—especially around the base of pallet racks. That’s where forklifts turn, pallets are loaded, and equipment constantly moves. It’s no surprise that the bottom few inches of a rack take the most hits. It might seem like a small detail, but damage here can lead to serious problems.

That’s why many warehouses rely on low-profile column guards. These small but mighty protectors shield the base of your racking system from the daily bumps, scrapes, and collisions that can lead to costly repairs—or worse.

What Makes the Bottom of a Pallet Rack So Vulnerable?

The lower part of a rack upright (aka the bottom 6 inches) is where all the action happens. Forklifts often pass close by. Pallets slide in and out. And most impacts—from blades, corners, or outriggers—happen right at floor level.

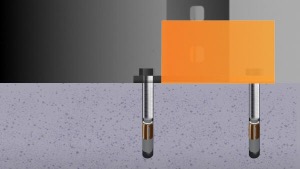

This spot also houses two critical components: the baseplate and the anchor. These pieces keep the rack stable and secure. If either one gets damaged, the entire structure can be compromised. That’s why it’s so important to protect them properly.

Why Baseplates and Anchors Matter

The baseplate is the flat steel piece at the bottom of a rack upright. It helps spread the weight of the rack to the floor, where the anchor bolts connect the rack to the concrete.

If the baseplate gets bent or damaged, the upright can lose its strength. If the anchors are loose or broken, the rack can start to lean or shift—especially in busy areas with lots of forklift traffic. That can lead to serious safety issues, including collapse.

Keeping the baseplate and anchors protected is key to making sure the rack stays stable and secure.

Low-Profile Column Guards Can Do a Big Job

Protecting the lower portion of pallet rack uprights with a low-profile steel guard helps preserve rack integrity, reduce the frequency of repairs, and prevent downtime. A 4-inch column guard or a 6-inch base guard are commonly used solutions. Though similar in purpose, each design has distinct characteristics that affect its use and placement in a warehouse environment.

The 4-Inch Rack Column Guard

Due to its small size, a 4-inch column guard occupies minimal floor space. It is especially useful in tight warehouse layouts where maximizing aisle clearance is critical. When independently anchored from the rack upright, the design avoids external anchor exposure, reducing the chance of contact with moving equipment.

A 6-Inch Rack Post Protector

A 6-inch rack protector that is directly anchored to the floor, completely independent of the racking structure, does not cover the column face, allowing beam installation at or near the floor level without obstruction. Some guards block the bottom beam holes, making it hard (or impossible) to place a beam near the floor. With a rack protector set slightly in front of the rack, you can still install beams low to the ground if your setup requires it. Additionally, the type of configuration enables the post protector to absorb forklift impact without transferring force to the rack structure itself. It also allows the guard to function with racks from different manufacturers and footplate sizes.

Which Rack Protector Is Right for You?

Both the 4-inch and 6-inch guards are engineered to protect the vulnerable lower area of warehouse racking: the bottom of the rack upright. The selection between them often depends on the layout of the warehouse, the types of impacts anticipated, and the rack configurations in use.

Final Thoughts About Low Rack Column Protectors

In a warehouse, it’s often the little things that make the biggest difference. Damage to the lower portion of pallet rack uprights might not seem like a big deal—until it causes a misalignment, a failed anchor, or an unexpected shutdown.

That’s where low-profile column guards come in. Whether you go with the 4-inch guard or the 6-inch version, both are smart solutions for keeping your racking systems stable, safe, and ready for action.

A properly designed guard focuses on the most vulnerable zone, using high-strength materials, compact dimensions, and an independent anchoring system to deliver targeted protection. When used in conjunction with broader warehouse safety measures, column guards form a small but important part of a comprehensive rack safety program.