License Plating for Optimal Traceability

Guest blog from MHI Member Company Smith Corona

From the moment a shipment arrives in the receiving dock, it is imperative that the contents are identified and its location is followed throughout the warehouse process. Knowing what product you have and where it is at a moment’s notice is an assured way to maximize warehouse efficiency and management.

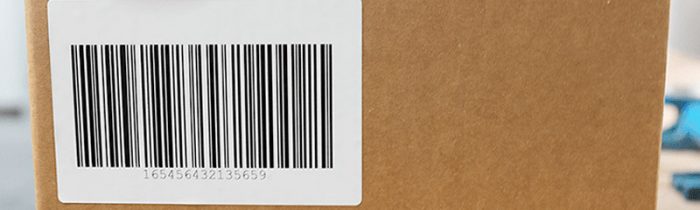

Here is where license plating comes in handy. This method of optimizing information eases the strain of warehouse hardships so manufacturers are able to track and access critical data with the simple scan of a barcode.

Let’s take a look at how license plating works and why it might be the right choice for your business.

What is License Plating?

Simply put, license plating is a management system that groups together any set of materials or products and marks it with a unique license plate number, or LPN for short.

License plating can simplify inventory tracking by helping to scale down large shipments of products. Small batches of items can be grouped into a box, which can then be grouped onto a pallet, which can then be grouped onto a truckload, and so on.

When that product makes its way to a warehouse, receiving is faster and easier with the scan of a single license plate at each stage instead of scans for each individual item. This means license plating can also aid in each stage of the warehouse process: receiving, work-in-progress, picking, and finished goods.

What Information Does a License Plate Include?

Because license plates are printed for grouped quantities of materials, the information contained within them can be quite extensive. These groups can be the same or mixed products. Luckily, barcode technology makes accessing and tracking this information faster with better visibility.

A license plate can include the following data:

- ● Part numbers

- ● Lot numbers

- ● Serial numbers

- ● Location

- ● Inventory status

- ● Quantity

In instances where the items being grouped contains consumable product, it is imperative that the license plate also contain the following data for better picking and stock rotation:

- ● Production/manufacturing date

- ● Expiration date

One scan of a license plate will be able to relay all of this detailed information for:

- ● Faster operations

- ● Improved productivity

- ● Fewer Errors

- ● Proper location

- ● Easier management of shipments and products

How Can License Plating Help?

Also known as pallet labeling, license plating moves merchandise more quickly from one location to another through the warehouse. It is extremely useful when it becomes difficult to track, locate, or identify pallets or cases throughout a warehouse’s infrastructure.

Warehouses are able to better optimize their space and business operations if they have a better understanding of their stock inventory. Manual data entry wastes time and can be fraught with human errors, but with one scan of a license plate, all of the necessary information can be accessed, leading to more efficient inventory control.

Since inventory is easily traced, license plates make managing warehouses overall less complicated. It can assist with picking the correct stock in a timely manner, faster material movement, and accurately planning for future inventory needs.

License plating can be found in both inbound and outbound processes. Shipments leaving facilities can be packaged for efficient transactions and warehouses receiving shipments can easily group products together, reducing the number of scans needed and overall reducing the time spent processing orders.

Where Can License Plates Be Found?

License plates can be beneficial in many settings, like warehouses and distribution centers, as well as with many different kinds of manufacturers. Here they can be attributed to many kinds of containers: pallets, cases, bins, freights, trucks, and many more.

Receiving

License plates maximize receiving shipments as incoming materials can be entered into a system faster by scanning a single barcode. Shipments can be packed or unpacked, split or combined. Multiple items can be received and stored together under a new license plate number.

Shipping

Since license plates are used for traceability, tracking shipments can improve accuracy and overall customer satisfaction. Pallets can be tracked along their route of the supply chain, informing both suppliers and customers about the exact time it will take for a shipment to arrive.

Around the Warehouse

Items stored in warehouses utilize license plates to speed up picking and accurately store and trace goods. Material use is able to be closely monitored for reorders. Items are able to be better organized which leads to more simplified forms of picking and overall better management.

Food Supply Chains

Any supply chains that involve food and consumable products use license plates not only for inventory and supply chain management but also the traceability of items in the event of a product recall.

In this instance, it is critical that damaged or defective products are rapidly traced back to their point of origin to prevent consumers from becoming ill as well as to minimize loss in profits. License plates can also be employed to better enforce stock rotation for FIFO (first in, first out) picking.

Why Use Pre-Printed License Plate Labels?

It is important to make sure that your license plates are impeccably printed so they can easily scan. Any smudged or faded labels will have difficulty being read by a scanner, delaying production and costing time and money.

Perhaps the biggest error that can be made with license plates is duplicate numbers. Because each license plate is given its own unique barcode number, duplicating a barcode will lead to errors throughout its entire warehouse process.

For example, a pallet labeled with a duplicate license plate can consist of the wrong product information, location, receiving and shipping information, all of which defeats the purpose of using a license plate in the first place.

There are two ways to procure license plates: print them yourself or have an outside source pre-print the labels for you.

In-House Printing

While printing these labels in-house is an option, it does require the proper equipment to produce. Those looking to print these labels on their own will need:

- ● A thermal printer

- ● Labels and ribbons

- ● Label rewinder

- ● Barcoding software

- ● Additional staff

There are several drawbacks to using this option. Operating through in-house printing can cause mishaps with low supplies, equipment malfunctions, and human error, all of which are detrimental to warehouse management and supply chain costs.

Pre-Printed LPNs

Having license plate labels pre-printed by an outside source is a preferred choice. Workers are able to apply labels on demand when products arrive, reducing processing times and cutting costs all around. Labels simply need to be reordered when supplies are running low.

This preference means less time wasted having to create and print your own labels, less money being spent on supplies used to print in-house, and less labor necessary to run the equipment, which can reduce the number of duplications and errors.

Pre-printed labels means:

- ● Increased accuracy

- ● Increased efficiency

- ● Increased speed

- ● Reduced errors

- ● Reduced costs

To learn more about how license plating can help your operation, contact one of MHI’s members like Smith Corona Labels today.