Synchronizing Cranes: Wireless Control for Tandem & Multi-Crane Operations

In heavy-lift and material handling environments, crane systems are often expected to perform in unison—whether it’s multiple bridge cranes working in tandem, dual hoists lifting a single load, or several machine axes coordinating a complex motion. Ensuring these cranes act as one system requires more than mechanical strength: it demands precise control, reliable communication and robust safety integration.

The challenge of crane-to-crane coordination

When two or more cranes lift or move a single load, even slight misalignment in speed or timing can lead to load swing, uneven strain, or hazardous conditions. Traditional wired control systems may limit flexibility, require extensive cabling, and can introduce latency or signal degradation under real-world conditions. In many facilities, the following issues emerge:

• Cabling complexity: Each crane must be connected with cables linking control panels, limit switches, and synchronisation circuits. This becomes problematic in retrofit scenarios or where travel spans are large.

• Latency and interference: As control signals traverse long cables or multiple interconnects, timing drift or noise may impair synchronous operation.

• Limited operator positioning: Wired remotes often require the operator to remain near control consoles or tethered to the crane, reducing visibility and access.

• Safety integration: For dual-crane and tandem lifts, safety-critical functions (e.g., emergency-stop, fault detection, motor interlocking) must be coordinated across systems—not simply replicated.

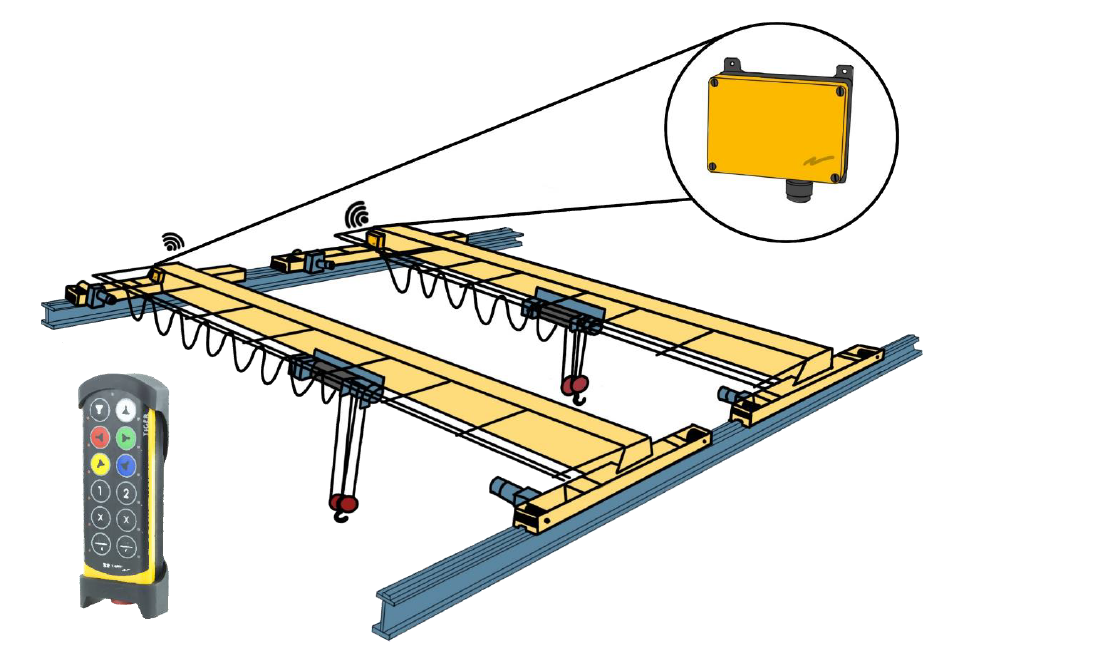

Wireless control systems: enabling coordinated lifts

Wireless crane-to-crane control systems address these challenges by replacing cables with reliable radio links and integrating safety and control logic into modular, portable systems. Key technical aspects include:

Duplex communication for synchronous operation

Duplex (two-way) communication between transmitters and a multichannel receiver allows real-time status and commands to flow between cranes. In a tandem lift, the lead crane’s transmitter sends control data, while the second crane receives mirrored commands, ensuring both movements stay in sync. The receiver monitors feedback signals (position, load, speed) and issues alarms or stops if divergence occurs.

Time-aligned motion control

Precision is achieved through algorithms that maintain constant speed ratios and synchronous stopping. For example, when two cranes commence motion, the system calculates speed set-points and begins both drives simultaneously; at the target position, both stop together. Any deviation beyond a defined tolerance triggers a controlled deceleration or emergency stop, maintaining safety and load integrity.

Modular receiver architecture

Modern wireless control systems feature modular receivers with configurable relays, analog/digital I/O, and safety logic cards. This allows integrators to adapt to different crane types, motor configurations and field-bus protocols. Depending on the installation, a receiver may control multiple motor drives, track speed sensors or interface with a building-management system—all without rewiring the main panel.

Ergonomic transmitters and operator flexibility

Wireless remotes offer operators freedom of motion and improved visibility. Transmitters with ergonomic push-buttons or joysticks can be configured for either crane in a tandem setup, and change-over is simplified: pairing a second transmitter involves minimal steps, reducing downtime when adding operators or replacing units. Operator-feedback features such as status LEDs or LCDs help confirm correct function in real time.

Safety certification and reliability

Tandem and multi-crane applications often require stringent safety integrity levels (SIL) or performance levels (PL) for emergency stop, load monitoring and interlock functions. Wireless systems must therefore meet redundancy, fault-detection and safe-state requirements. Robust housings (e.g. IP65 ratings), battery-backup and dual communication channels enhance both reliability and uptime.

Why this matters for OEMs and integrators

For OEMs and integrators, leveraging a pre-engineered wireless control system presents several advantages:

• Reduced installation time and cost: Eliminating bulky cable runs simplifies layout, reduces downtime and enables retrofits in existing cranes.

• Scalable system design: A modular receiver platform allows for expansion or re-assignment of equipment without major rewiring.

• Improved operator safety and productivity: Wireless control allows better vantage points, reduces cable-based trip hazards and enhances response times.

• Enhanced support and serviceability: With standardized modules and local stock availability, service teams can respond quickly to relay replacements, software updates or transmitter swaps.

Closing note

Wireless control is no longer a novelty in material-handling applications—it is an integral part of safe, efficient crane systems. For crane-to-crane and tandem operations, the coordination, flexibility and safety benefits are substantial. Companies such as Tele Radio have developed certified wireless control solutions that enable synchronized crane lifts, improved operator ergonomics and streamlined installations.

By choosing systems that integrate advanced communication, safety logic and field-proven architecture, OEMs and integrators can deliver equipment that meets today’s demands for precision, uptime and operator welfare.