Use These Ergonomic Tools To Lessen The Risk Of Wrist Injuries

Blog post by MHI Ergonomics and Safety

The most recent data from the Bureau of Labor Statistics documenting nonfatal injuries and illnesses in 2019 found that warehousing and storage workers sustained 1,020 wrist injuries that kept them out of work for multiple days. These injuries resulted in the average workers’ compensation claim of $24,627, according to the National Safety Council, which specifically cites sprains/strains as costing $31,851 and carpal tunnel syndrome as costing $30,510 in workers’ comp.

Wrist injuries associated with manual material handling are frequently caused by repetitive movement, overuse, pushing or pulling static loads across surfaces that present a high degree of friction, or constant vibration. However, by implementing certain types of ergonomic assist equipment and devices, the chance of a worker injuring one or both wrists on the job can be reduced. By supporting associates as they perform tasks, these ergonomic solutions minimize the impact of performing repetitive motions. They include:

Workstation Enhancements: Adjustable height ergonomic workstations ensure that each individual can raise or lower the work surface to match their height and keep all tools and equipment within easy reach to minimize repetitive stresses and strains. Workstations that require the use of a keyboard and/or mouse can be outfitted with wrist-rests made of soft gel that conforms to the user’s wrists and support proper hand positioning. Using these supports keeps the wrists in a neutral position; that is, one that is not excessively bent up or down. Additionally, adding an adjustable, tilting tray on or under the workstation enables the user to angle the keyboard to the most ergonomic position that best supports natural movement.

Further, when specifying a workstation’s surface, those that are equipped with rounded or rolled edges — as opposed to 90-degree edges — create a softer, more ergonomic transition for the wrists. Workstations for tasks that require repeated pulling of items toward the body, such as packing boxes for outbound shipping, can be enhanced with integrated rollers or transfer balls to reduce the friction of the item as it passes over the surface to minimize the risk of wrist strains. Finally, automatic tape dispensers that eliminate the need to use a hand-held tape gun to seal packages closed can also reduce the strain on packers’ wrists.

Easy Rolling Casters: Used primarily on carts and bins, casters can reduce strain on many parts of the body — including the wrists — by design. Capable of rotating 360-degrees so the wheel rolls in any direction, casters permit greater maneuverability around corners. When outfitted with harder tread materials (such as nylon, polypropylene, steel or cast iron), they have lower starting and rolling resistance, and are less affected by compression caused by a heavy load. This means they require less manual force for pushing and pulling, minimizing wrist strains.

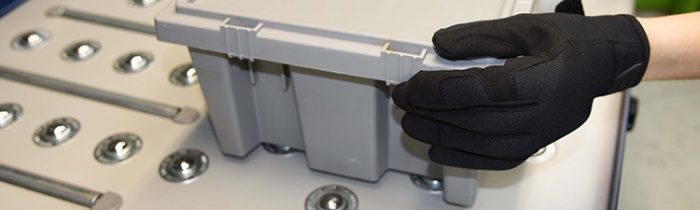

Vibration Avoidance: In facilities where heavy equipment is operating consistently, vibration can become a problem for employees working nearby. If possible, move those employees’ workstations as far away as possible from the vibration source. For processes that require the use of hand-held power tools, which also produce vibration, the tools should be outfitted with handles designed to reduce the amount of shaking the worker experiences. There are also padded gloves and hand/wrist guards specifically designed to be worn by users of such tools that minimize the impact of vibration. Likewise, giving power tool operators other tasks that allow them to rest and do other things can help reduce the cumulative effect of repetitive use.

Looking for more ways to improve ergonomics in your manual material handling operation? Download the free publication, “Ergonomic Guidelines for Manual Material Handling,” published by the members of MHI’s Ergonomic Assist Systems & Equipment (EASE) Industry Group.