8 Benefits of Repair vs. Replace: Best Solutions for Rack Damage

Guest blog by MHI member Damotech

Imagine this: your warehouse is running smoothly, meeting deadlines, and keeping customers happy. Then, a forklift collides with a rack upright. Suddenly, you’re dealing with a familiar disruption—replacing the entire column. Inventory needs to be moved, space cleared, and inventory recounted. The new part takes weeks to arrive, and installation means unloading, dismantling, and rebuilding the rack section. Even after all that, similar damage could happen again, bringing you right back to the same situation.

This article outlines the differences between replacing a damaged rack and using engineered rack repair kits, along with eight practical benefits of choosing repair over full replacement.

The Real Cost of Rack Replacement

When a warehouse rack is damaged, the instinctive response is often to replace the entire upright with an OEM (Original Equipment Manufacturer) part. However, this approach often results in significant operational impact. First, a compatible replacement must be sourced, which can take weeks or even months, depending on availability. During this time, the damaged rack remains a risk to safety and productivity.

Once the part arrives, all surrounding bays must be emptied, requiring temporary storage for inventory. This increases the chance of product misplacement and requires additional labor. Dismantling the upright involves removing beam levels, baseplates, and anchors, and—depending on site conditions—temporarily addressing nearby utilities or obstructions, depending on the rack height.

Reassembly is time-consuming and must follow the original specifications. After the upright is reinstalled and the rack is reloaded, the risk of repeat damage remains, potentially creating an ongoing cycle of repair and disruption.

Rack Repair: An Alternative Approach

In contrast, using engineered rack repair kits allows only the damaged portion of the upright to be restored, minimizing time, labor, and disruption. This method has been used successfully in large-scale facilities and offers specific operational advantages.

Time & Cost

1. Time Efficiency

Repair kits are designed for fast installation, often under an hour. Only the damaged section typically needs to be unloaded, while the rest of the rack remains in use. This targeted approach significantly reduces downtime and helps maintain productivity.

2. Cost Savings

Replacing an upright involves part cost, shipping, labor, equipment rentals, and operational delays. Replacement parts can also incur higher shipping costs due to size and weight—often up to four times more. Repair kits help reduce costs related to materials, labor, and shipping.

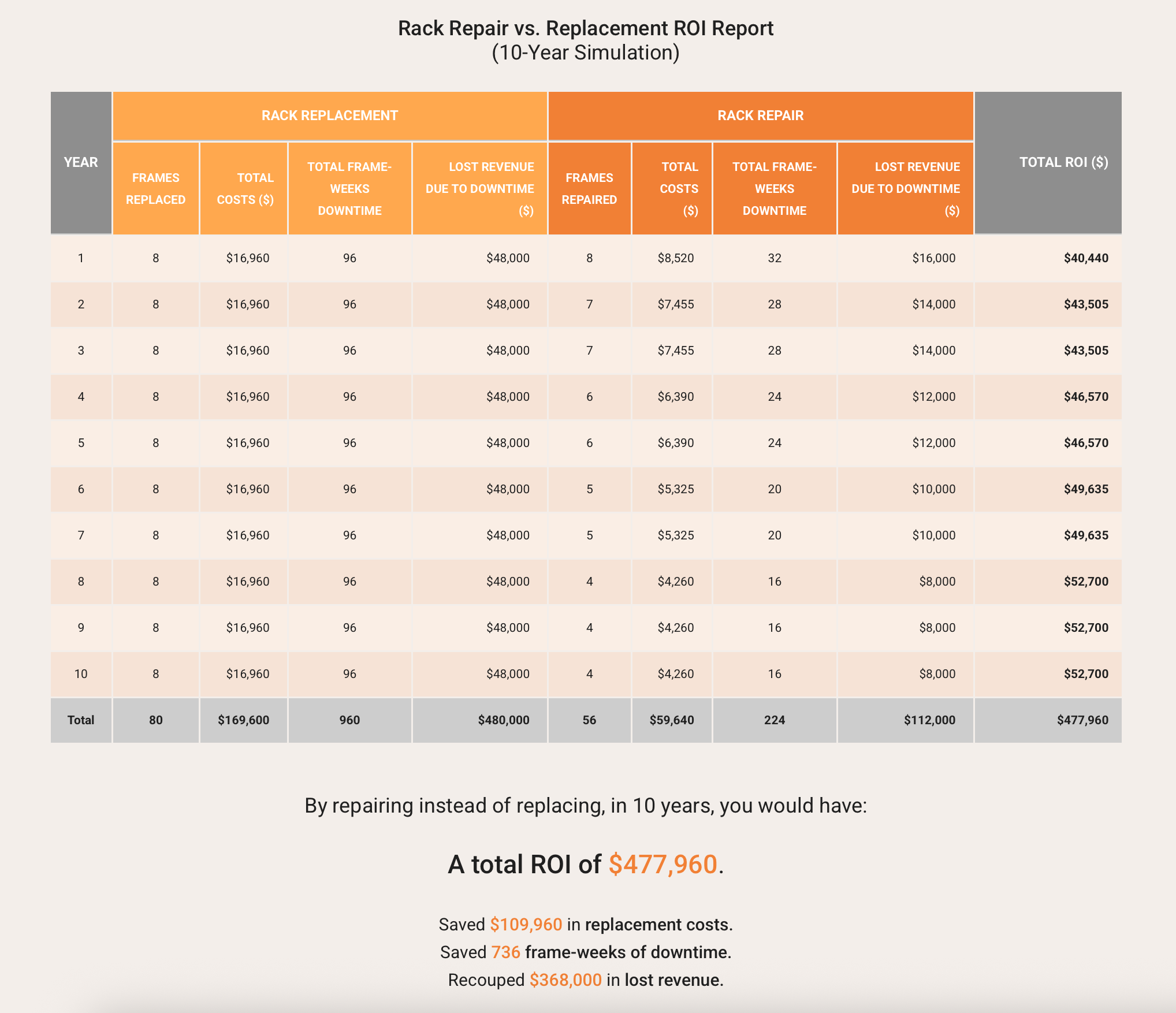

10-Year Simulated ROI: $477,960 —Projected savings from repairing rack frames instead of replacing them. Click on the graphic to enlarge it.

3. Engineered for Performance

Repair kits can be custom-built to match the original racking system and restore its structural capacity. Make sure to choose that meets industry standards and safety requirements.

4. Enhanced Protection

Repair kits restore function while adding protection. Many include integrated deflectors to redirect future impacts. Compared to standard uprights, the use of thick structural steel components improves durability and impact resistance.

5. Compatibility with Most Rack Types

Repair kits are designed to fit various rack styles—roll-formed or structural—and are compatible with different punch types and rack manufacturers. They are also available in multiple colors to match existing systems for a uniform appearance.

Continuity & Risk

6. Reduced Operational Disruption

Rack repair minimizes disruption. Since only the damaged section needs unloading and the rest of the system remains intact, installations are faster and less invasive than full replacements. This is especially beneficial in high-traffic environments.

7. Warranty Coverage (Lifetime on Some Kits)

Many repair kits include a lifetime warranty that cover the product for as long as the racking system remains in service. This warranty protects against defects in design, materials, and workmanship. If damage occurs under normal use, the kit can be repaired or replaced without added cost. Including warranty coverage in a repair solution can support long-term maintenance planning and reduce future repair expenses.

8. Environmental Considerations

Repairing instead of replacing reduces waste. Replacing an entire upright typically discards large sections of steel that are still functional. Repair targets only the damaged area, conserving material and reducing environmental impact.

Conclusion: Choosing the Right Approach for Rack Damage Management

When warehouse racking is damaged, full replacement is often assumed to be the best option. But it comes with delays, higher costs, and potential repeat issues. Engineered rack repair provides a targeted, efficient, and durable solution.

Repair kits help maintain rack integrity, reduce downtime, and extend the system’s lifespan by restoring only the affected section without unnecessary waste or disruption.