10 Safety Tips for Warehouse Automation Programs

Guest blog by MHI Member KPI Solutions

To celebrate National Safety Month, we at KPI Solutions want to emphasize the importance of safety in warehouse environments, particularly around automated systems. Our goal with this blog post is to not only inform but also to help cultivate environments where safety measures and automated systems are effectively synchronized, ensuring optimal performance and safety.

Emphasizing Safety in Automated Warehouse Environments

At KPI Solutions, we understand that every automated warehouse is unique, characterized by its own set of challenges and needs. As leaders in warehouse automation and material handling, our comprehensive approach ensures that safety is not an afterthought but a cornerstone of operational planning and execution. A critical component of this approach is the creation of a safety-first culture, where every employee feels responsible not only for their own safety but also for that of their colleagues. This culture is supported by clear communication, routine safety audits, and a shared commitment to maintaining a secure working environment.

1. Understanding Automation Capabilities

Automation is revolutionizing warehouse operations, making them more efficient and less reliant on manual labor. However, the successful integration of these technologies requires a thorough understanding of what automated systems can and cannot do. Recognizing these boundaries not only enhances efficiency but also ensures that human interactions with these systems are safe and predictable.

2. Comprehensive Training Programs

Training is crucial in ensuring that all employees understand how to interact safely with new technologies. At KPI Solutions, we advocate for rigorous training programs that cover operational procedures, emergency responses, and day-to-day interactions with automated systems. By preparing your staff with comprehensive knowledge, you significantly reduce the risk of accidents.

3. Stay In Designated Areas

Designating specific areas for automated operations helps prevent unauthorized access and minimizes the risk of accidents. These zones should be clearly marked and communicated to all staff members, ensuring that only trained personnel interact with complex machinery, further safeguarding their well-being.

4. Wearing Appropriate Safety Gear

Personal protective equipment (PPE) is crucial for maintaining safety in automated environments. Recommendations for PPE should be tailored based on the specific needs of each job site and client requirement, ensuring all personnel are properly protected with essential gear like helmets, safety shoes, and high-visibility vests.

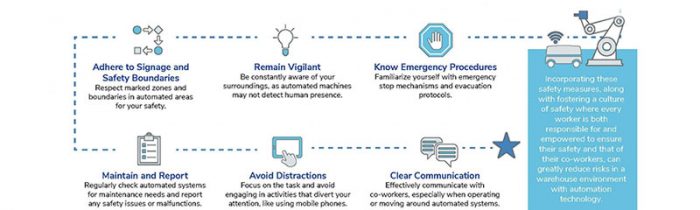

5. Know Emergency Procedures

Understanding emergency procedures is vital for ensuring a quick and efficient response in emergencies. Equally crucial is the implementation of Lock Out, Tag out (LOTO) protocols, which safeguard maintenance staff by ensuring machines are properly de-energized and isolated from power sources before any maintenance begins.

6. Remain Vigilant

Vigilance is key in environments where automated systems operate. Some systems, while advanced, may not always detect human presence. We encourage workers to be aware of their surroundings and the operational status of machinery around them at all times, thus preventing accidents before they occur.

7. Adhere to Signage and Safety Boundaries

Effective safety management includes clear and visible signage that denotes operational zones, safety hazards, and emergency exits. Respecting these signs and boundaries ensures that all personnel are aware of and adhere to safety protocols, reducing the likelihood of accidental breaches and injuries.

8. Maintain and Report

Routine maintenance and prompt reporting of any irregularities can significantly enhance operational safety. At KPI Solutions, we emphasize the importance of regular checks and encourage all employees to report any signs of malfunction or wear and tear. Proactive maintenance and reporting ensure that equipment operates safely and efficiently.

9. Avoid Distractions

In the digital age, distractions are more prevalent than ever. We advise all personnel to focus solely on their tasks and avoid engaging in activities that could divert their attention, such as using mobile phones. This focus is crucial for safety in areas where automated systems operate, as distractions can lead to critical errors.

10. Clear Communication

Effective communication is vital in automated environments. It ensures that all team members are aware of their roles and the statuses of operations, especially during shifts changes or when moving around automated systems. At KPI Solutions, we foster an environment where communication channels are open and clear, ensuring that every message related to safety and operations is conveyed accurately and received promptly.

Conclusion

By integrating these comprehensive safety measures, KPI Solutions not only ensures the efficiency and reliability of automated warehouse operations but also prioritizes the well-being of every individual involved. As we observe National Safety Month, let’s recommit to these essential practices, reinforcing a safety-first culture that defines the modern automated warehouse.