Dawn of the Planet of 3D Printing

by Sterling J. Scott, Marketing Communications Coordinator, MHI | @mhi_sterling

The 2014 MHI Annual Industry Report revealed that only 17% of executives view 3D printing as a strategic priority. This is understandable because 3D printing has not greatly impacted manufacturing or affected supply chains. However, less than a decade ago, the same could be said for internet retail and mobile shopping. Now, these technologies are fueling the emergence of same-day and next-day delivery. They also make it possible for smaller companies to deliver products to consumers as it eliminates the requirement of having a brick and mortar store.

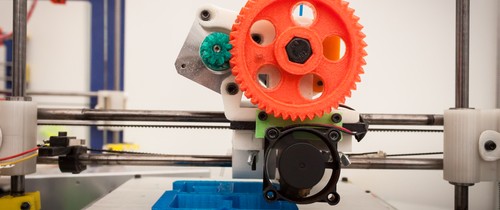

Companies have been developing commercial and industrial 3D printers for years; however, this technology may soon be available to consumers and more affordable for businesses due to the work of a few startups. Wired recently published an article about a startup that has developed a $250 3D printer and other startups that have developed 3D printers ranging from $300 to $500. The growing affordability of 3D printing technology does not pose a threat to the established manufacturing processes, the same way that internet retail has not posed a threat to most brick and mortar stores. However, like internet retail, it does change consumer expectations as well as level the playing field for smaller businesses. 3D printing should be a strategic priority. if not for implementation into the manufacturing process, for integration into the sales process.

3D printing has a lot of potential. Rather than manufacture, package, ship, and shelve products, companies can make some of their products available to purchase and download for 3D printing. When a company goes from selling a physical product to selling a design, the costs of doing business are lower. Also, in emerging markets where high capital investment is required to develop manufacturing facilities, infrastructure, and shipping routes, 3D printing may lower costs for businesses trying reach the growing consumer populations. An established distributor or partner with 3D printing can manufacture and distribute the products at a much lower cost.

While in all cases, there is the threat of someone reselling a printed product under another brand, that is a threat that already exists. The same precautions would have to be taken to ensure brand security. The same energy it would take to rebrand a purchased product for resale under a different brand or copy designs is the same energy it takes now to do the same for products not manufactured using 3D printers.

3D printing offers another means of purchase for consumers and has great potential in lowering supply chain costs, especially in reaching emerging markets. If businesses are not monitoring the emergence of 3D printing technology, then they should be, because consumer demand and market opportunities may make 3D printing a strategic priority for all.

To learn more about 3D printing technology and its potential impact on supply chains and material handling, download and read the 2014 MHI Annual Report at www.mhi.org.